Do you know how many components go into making a Swiss-made luxury mechanical watch?

Luxury mechanical watches are not just timekeeping devices; they are intricate pieces of art that combine craftsmanship, precision, and beauty. A Swiss mechanical timepiece is a marvel of engineering and craftsmanship. It can comprise hundreds of complex systems of gears, springs, dials and levers that work together in perfect harmony to keep time. These parts, or the watch anatomy, give it the aesthetic value coveted by connoisseurs and collectors alike.

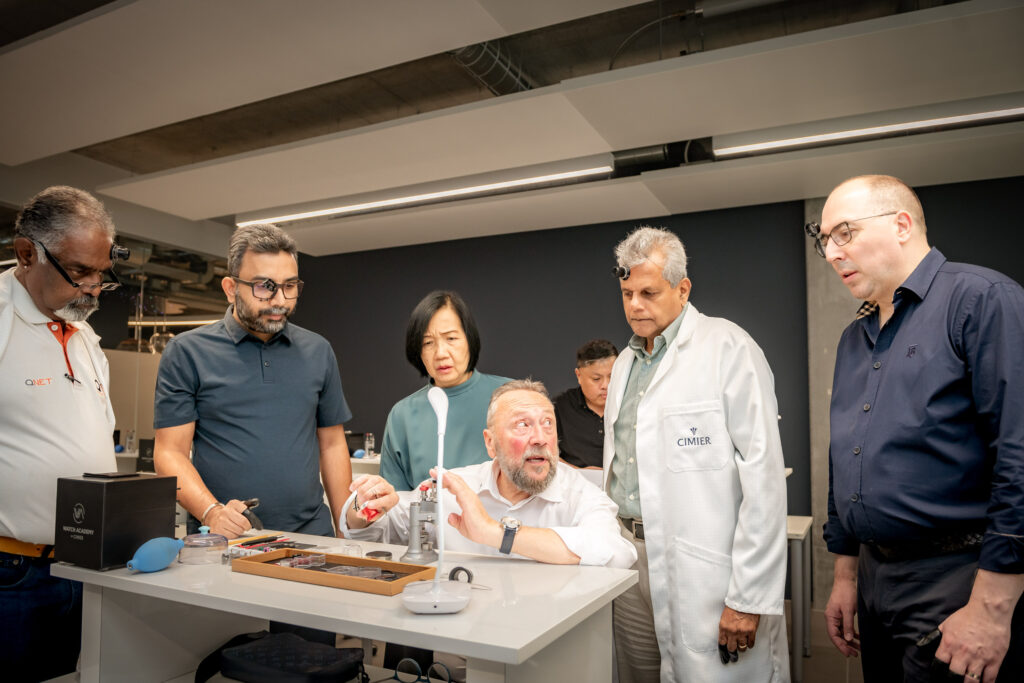

The QI Group acquired the luxury Swiss watch brand CIMIER in 2006. To mark QI Group’s 25th year of operations in 2023, our Founder and Executive Chairman Vijay Eswaran and Co-Founder and Deputy Chairman Joseph Bismark led our QI Board of Directors and top management to Switzerland back to the heart of CIMIER.

There, they had the opportunity to participate in the Watch Academy by CIMIER, a fascinating experience where they could step into the shoes of a watchmaker to create their customised watch.

CIMIER’s Watchmaker and Trainer, Justin McMahon, led the workshop with his team. They guided the QI delegation throughout the assembly process, from choosing a base model, four cases, four movements, four flanges, 17 handsets and 18 straps.

Assembling the more complex part of a mechanical watch, like the movement – the watch’s engine – gave the guests a new-found appreciation for the work of a watchmaker. The assembly of the escapement wheel, seating the jewels and balance spring attached to the balance bridge were particularly delicate operations.

They even learned how the power was transferred from the mainspring and through the gear train, then attempted to fix the dial on the movement, followed by the hands. Arguably the trickiest step was putting the small seconds hand in place. After the casing of the movement, the last operation involved attaching the leather strap and the buckle. Upon completion, each was presented with a certificate, a gift box and documentation of the watch.

CIMIER Trainer Justin shared that “the seconds hand is so tiny that putting it on is usually what people struggle with the most in the watch assembly process. The trick is to get used to looking through a magnifying glass and having steady hands. As a watchmaking instructor, seeing our guests’ satisfaction when they step back and look at the final timepiece they’ve just assembled is always rewarding.”

“It was lovely hosting the QI Founders, the Board of Directors, and the QNET Achiever’s Club at the Watch Academy by CIMIER. The past couple of years at CIMIER have been focused on building strong foundations for the brand and the company. CIMIER will celebrate its 100th anniversary in 2024, and we will announce new projects to commemorate this incredible milestone. Stay tuned!” remarked Alexandra Lanz, CEO of Montres CIMIER SA.

Find out more about the Watch Academy by CIMIER here.